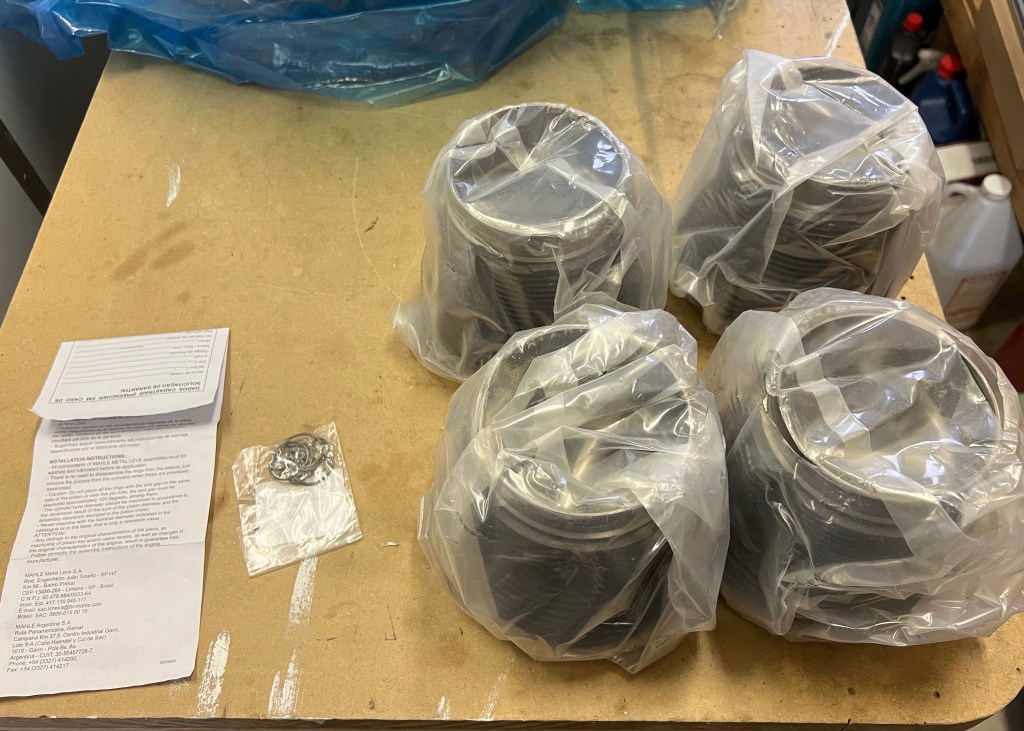

Today I painted the cylinders for my Aerovee. When I first received the engine kit I noticed that one box seemed to be a bit damaged on the corners. I took photos but upon further inspection found that the box contained my cylinders and they were fine. Since the cylinders were round the corner damage to the box did not affect the cylinders.

After opening the box I found the retainers for the piston pins in a bag as well as some assembly instructions in addition to the cylinders and the pistons inside them.

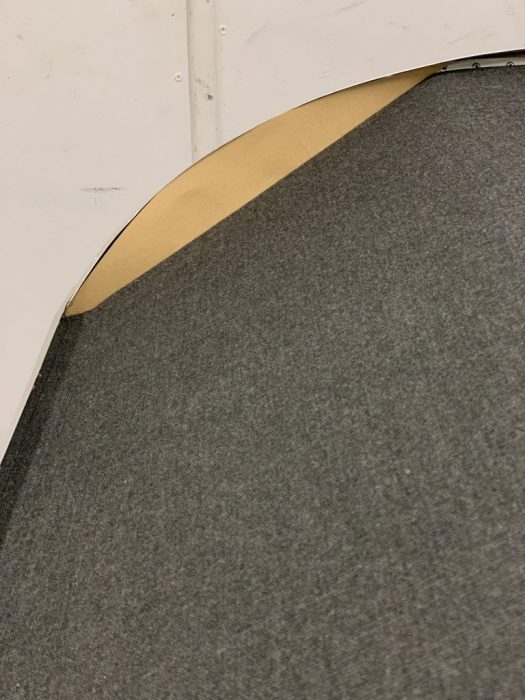

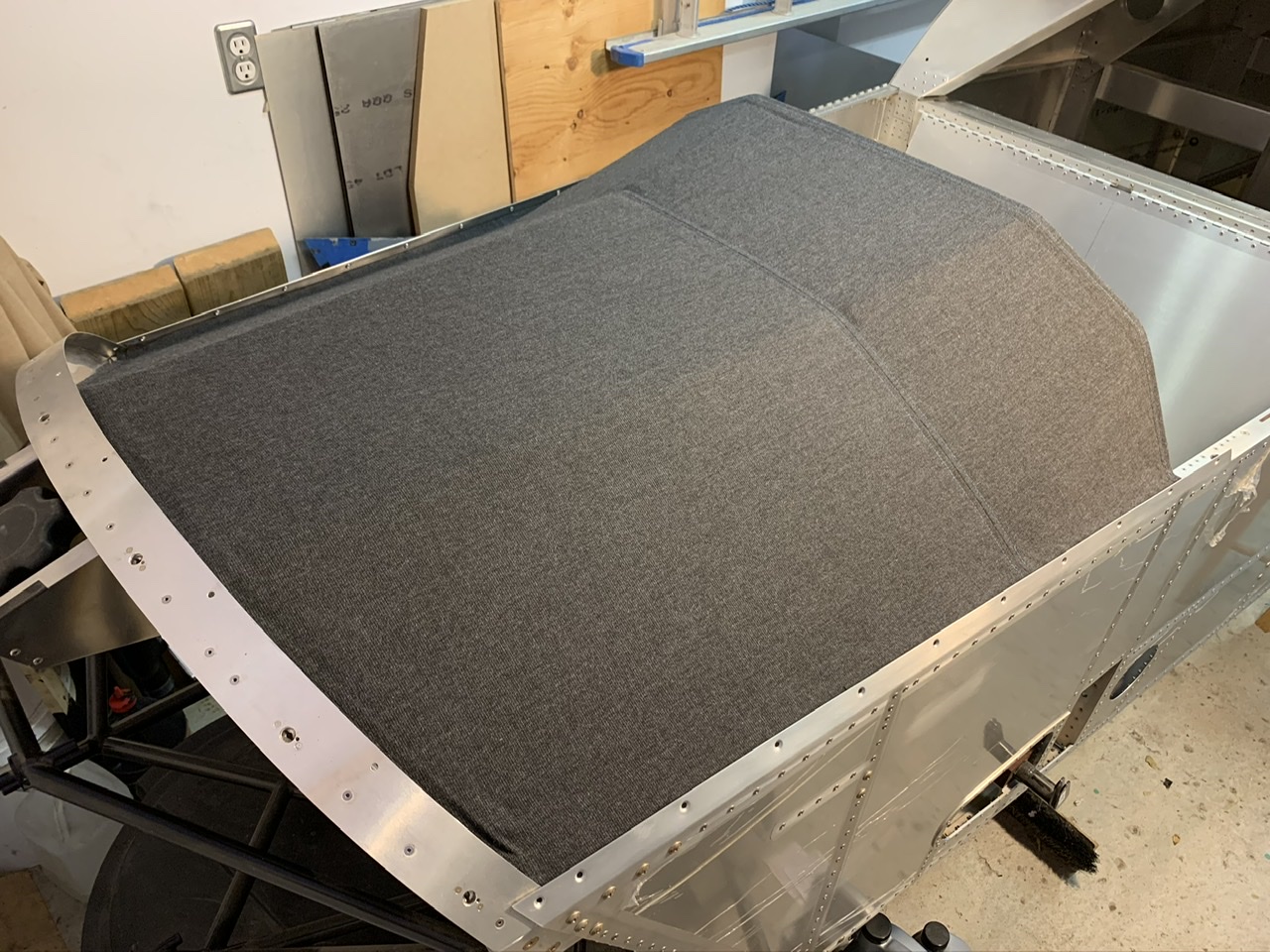

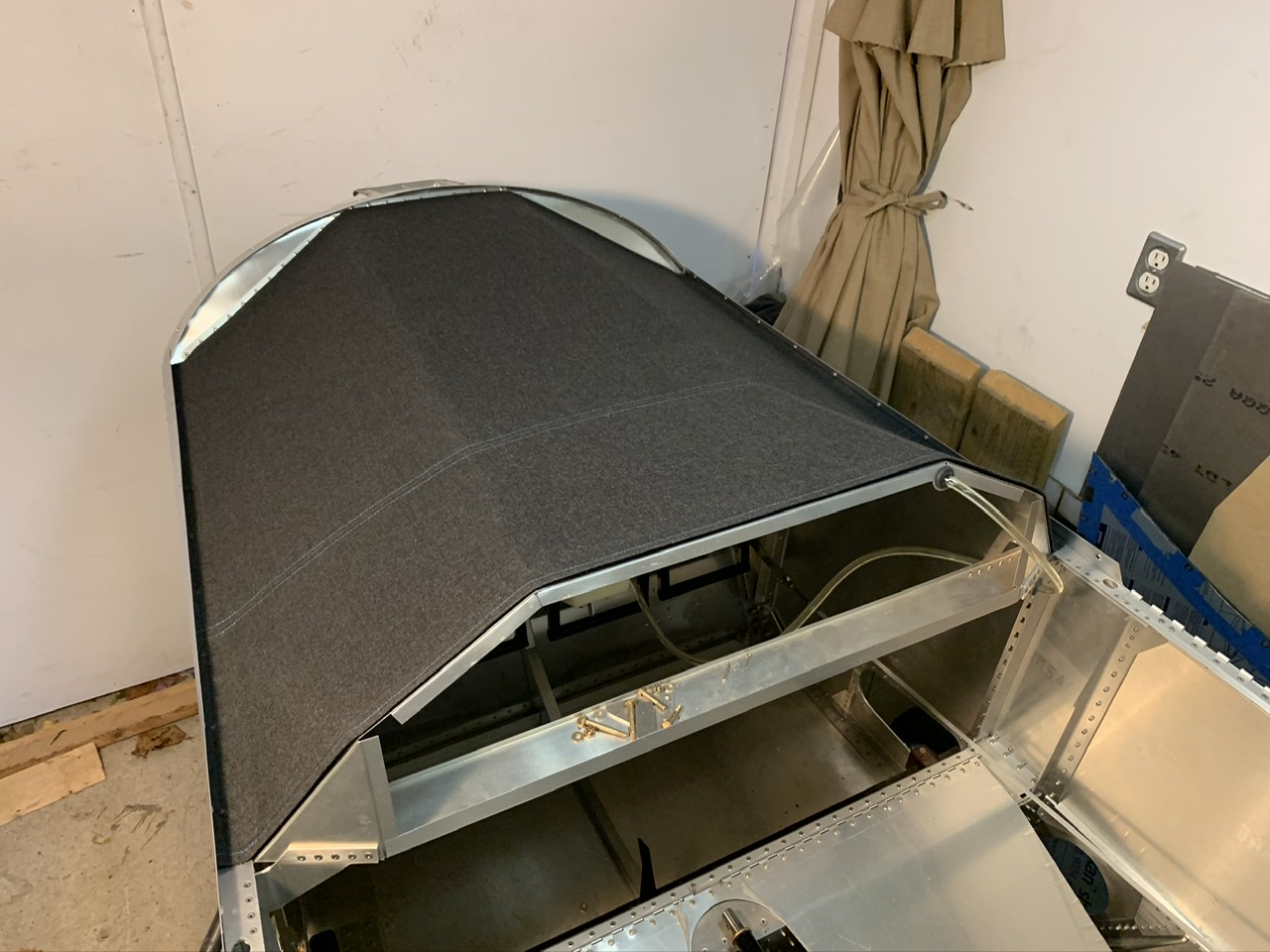

Next I proceeded to mask the cylinders with the pistons inside as shown in the AeroConversions assembly video. After getting the cylinders prepared I realized I would need different paint for these compared to the engine case. For the case, I just used a flat black enamel. The case should not exceed 400F. I had read in Bob Hoover’s blog (https://bobhooversblog.blogspot.com/2006/11/vw-case-paint.html) (https://bobhooversblog.blogspot.com/2006/11/vw-case-paint.html) that the cas should be fine painted in an oil based enamel.

I felt that, for the cylinders, a higher temperature paint would be more appropriate. BBQ flat black seems to be a common paint used and was recommended in the AeroConversions video. I bought a can of this for the cylinders.

You must be logged in to post a comment.