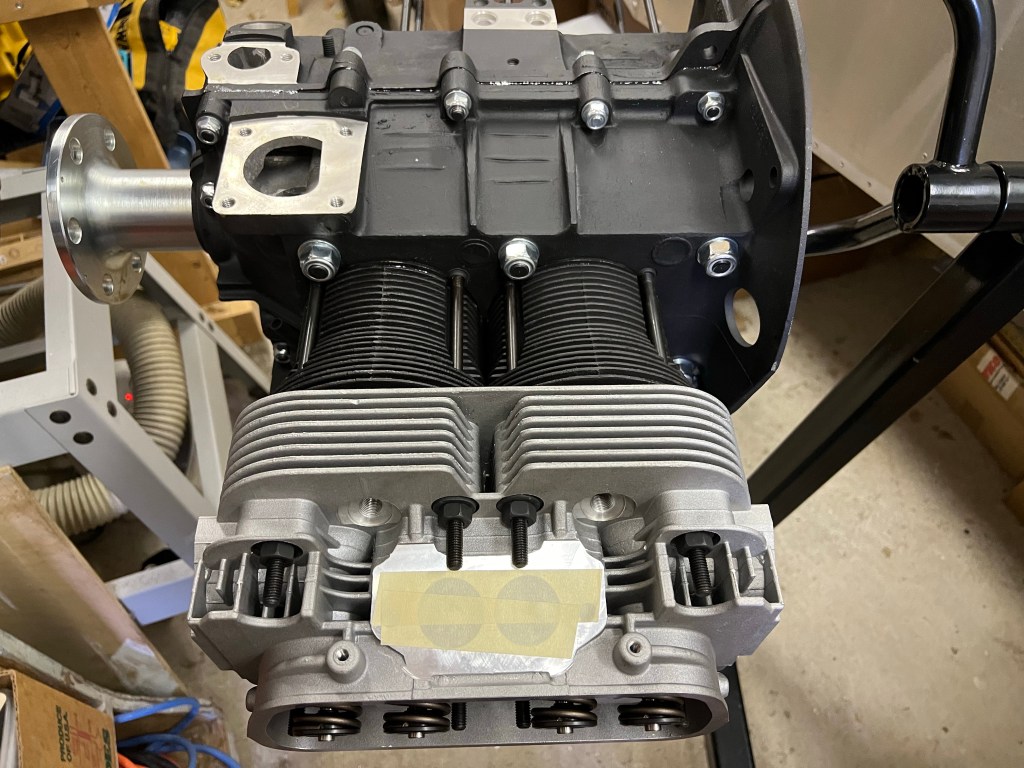

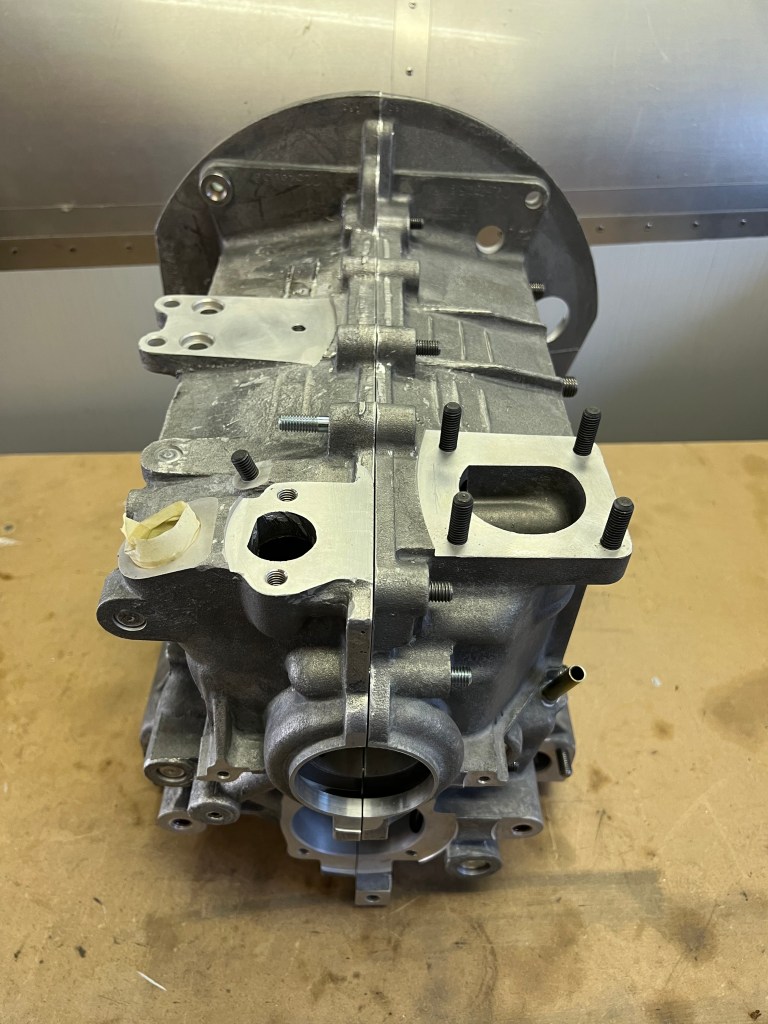

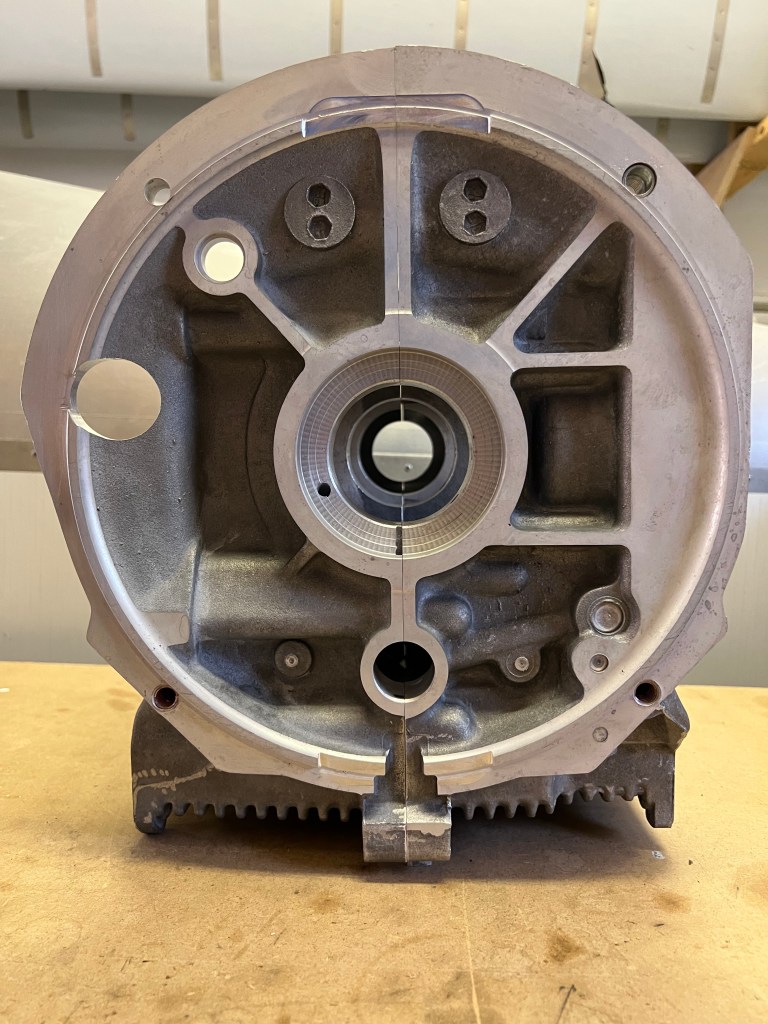

I worked on installing the cylinders, pistons and cylinder heads on one side of the engine today. My goal was to complete one side before starting the other. The reason for working on one side at a time was to try and ensure a good seal for the cylinders. I figured that if the cylinders were installed, but the cylinder heads were not, there would be no pressure to help seal the cylinders and allow the Permatex Aviation Form-A-Gasket #3 to seal properly. I’m not sure if this is entirely true. It claims to be non-hardening and slow-drying.

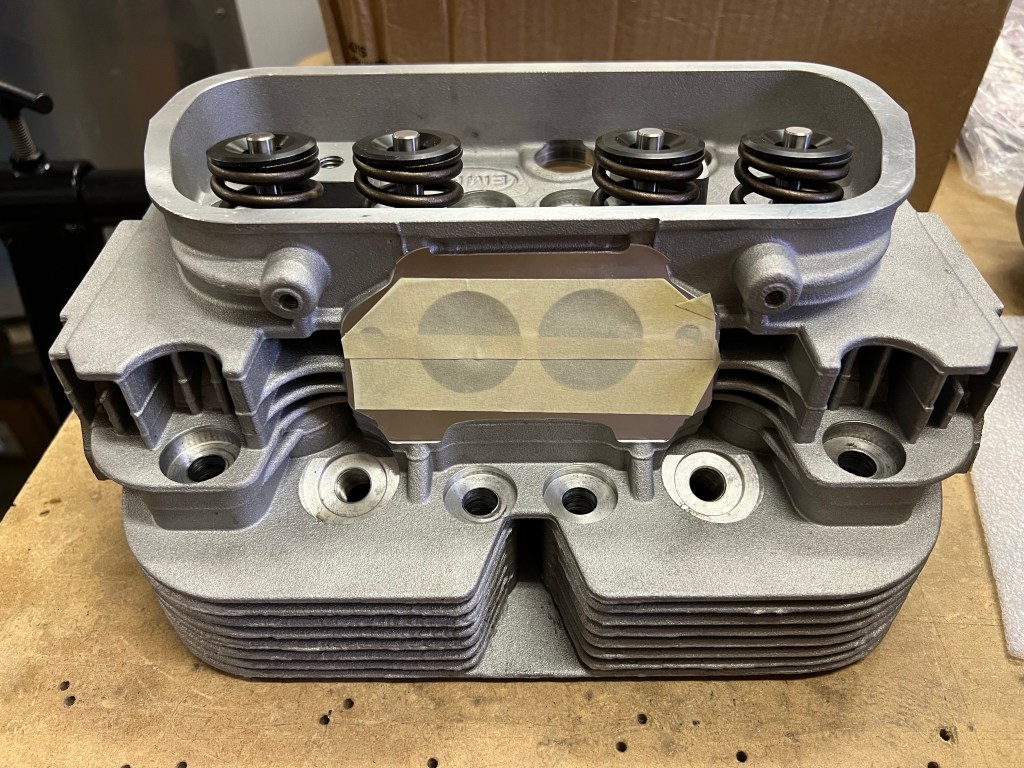

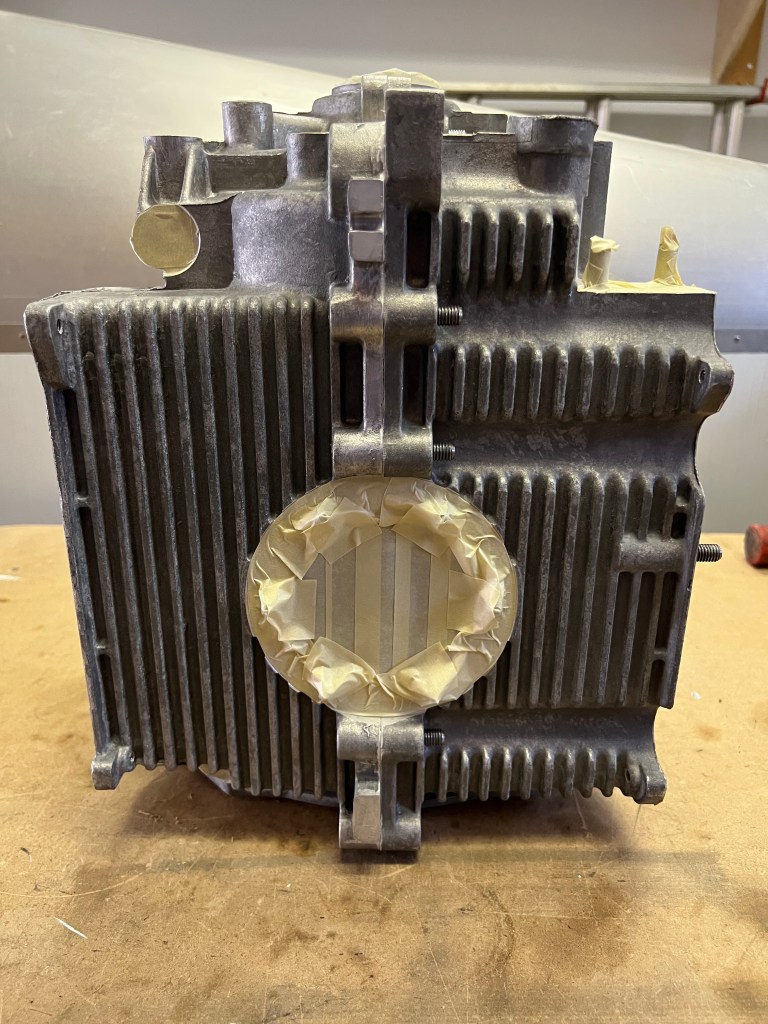

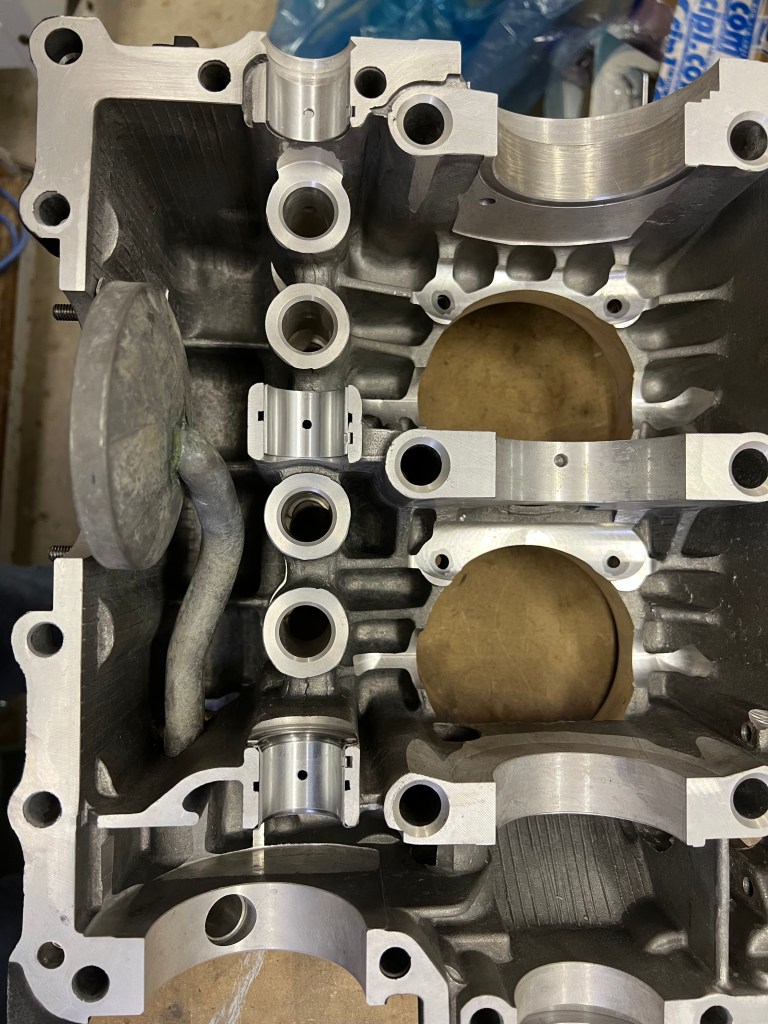

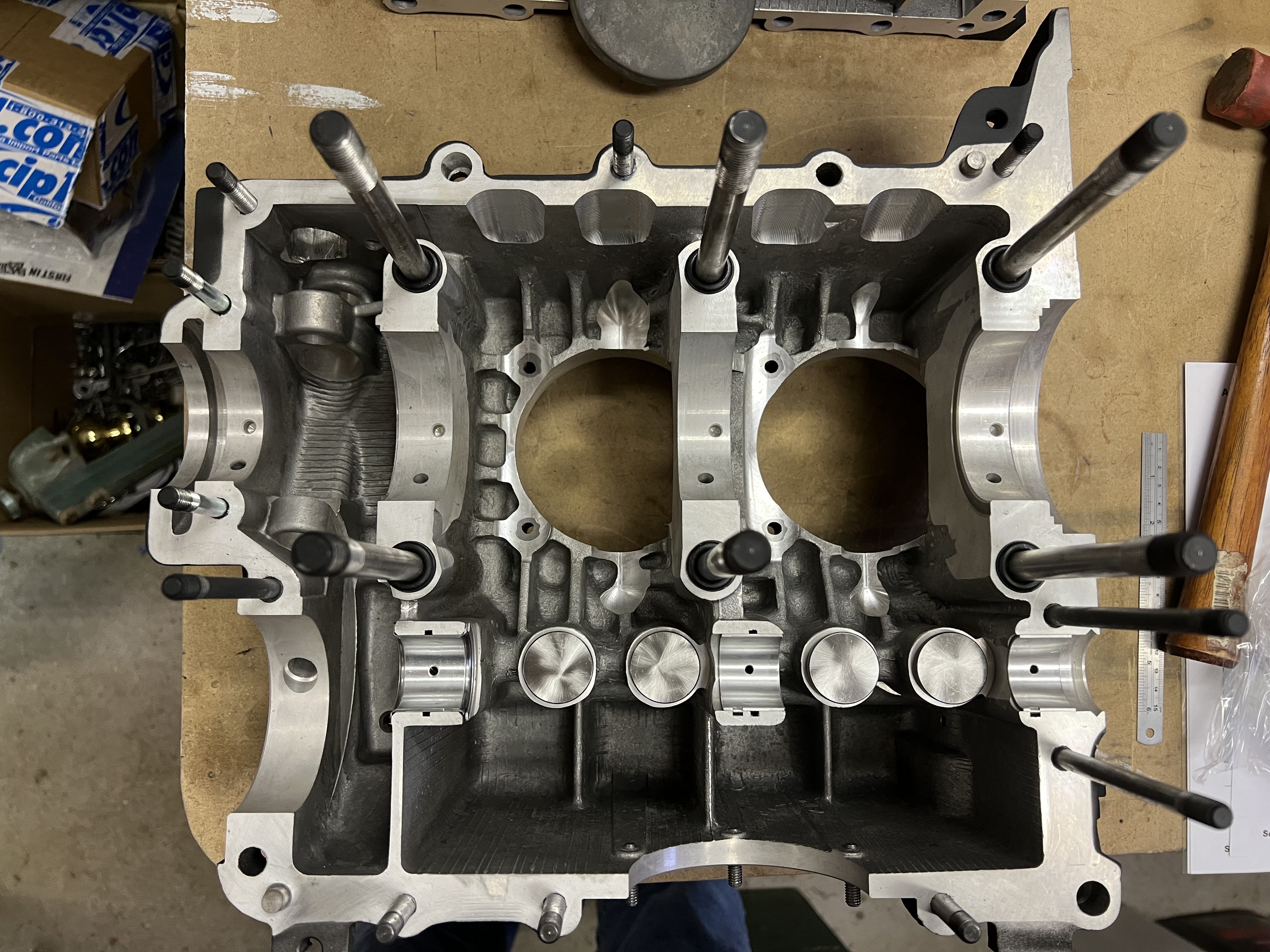

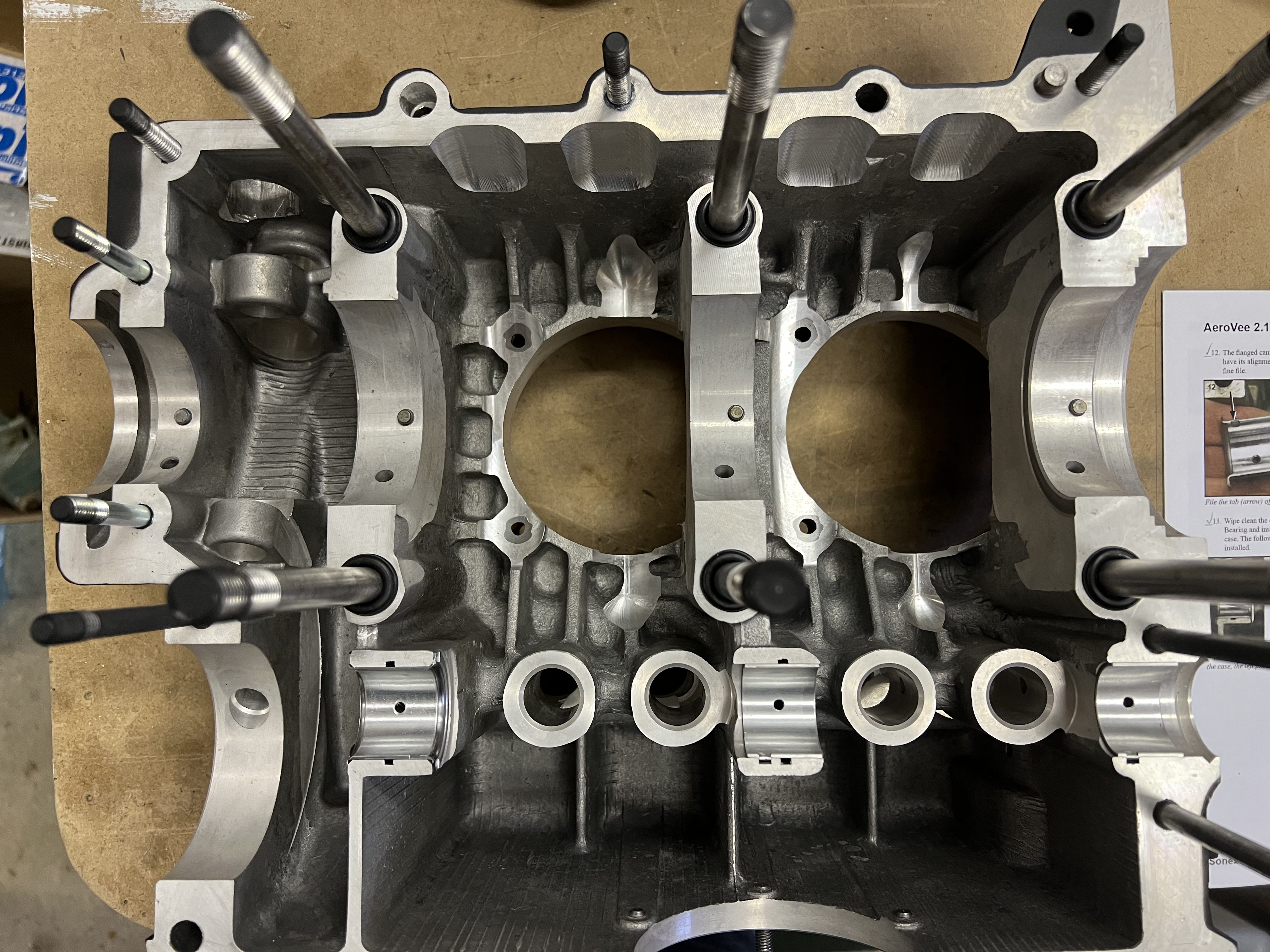

I started by reviewing the cylinder spacer selection based on wanting to run 8.0: 1 compression for aviation fuel. I used some mineral spirits to clean up excess oil from the mating surface of the cylinders and the spacers. Next, I checked the piston orientation in each of the two cylinders I was going to start with to be sure the arrows would be pointing to the flywheel. I pulled the pistons out the bottom of the cylinders enough to allow the wrist pins to slide out. I put the snap rings in one side of each piston so that I could install the pistons and still be able to put the snap rings in from the front and back of the pistons after sliding the wrist pins in.

Orienting the wrist pins required some though. For the first piston, it does not matter which direction the wrist pin slides in from. But when you install the second piston you have have the wrist pin slide in from the outside, away from the first cylinder.

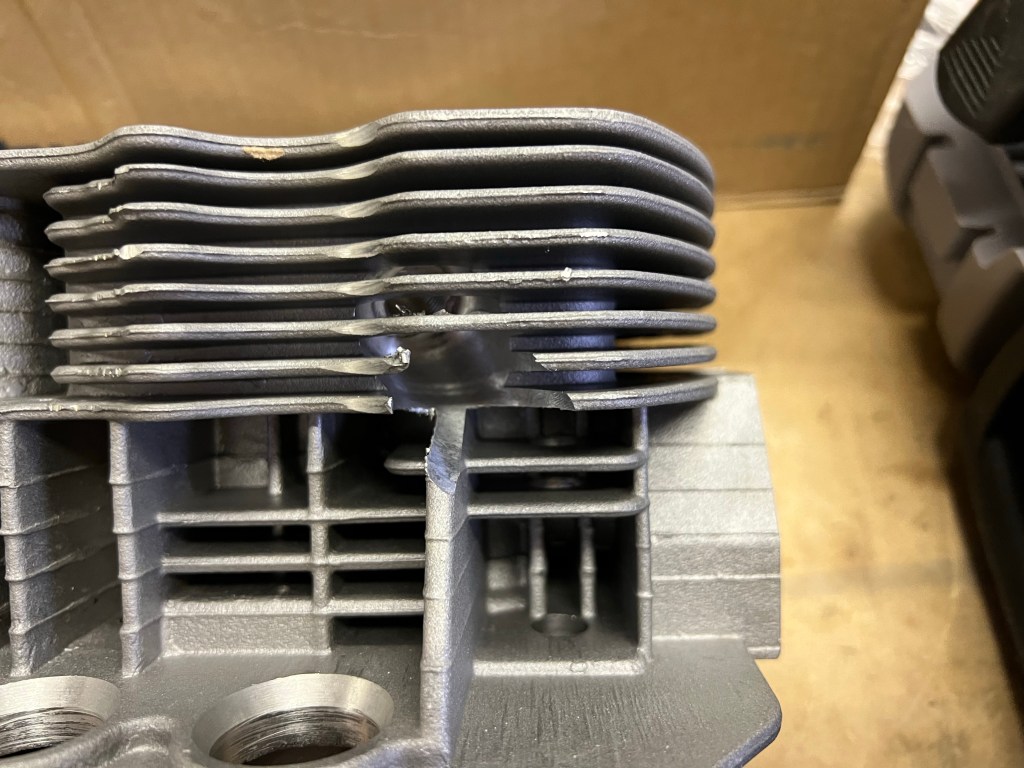

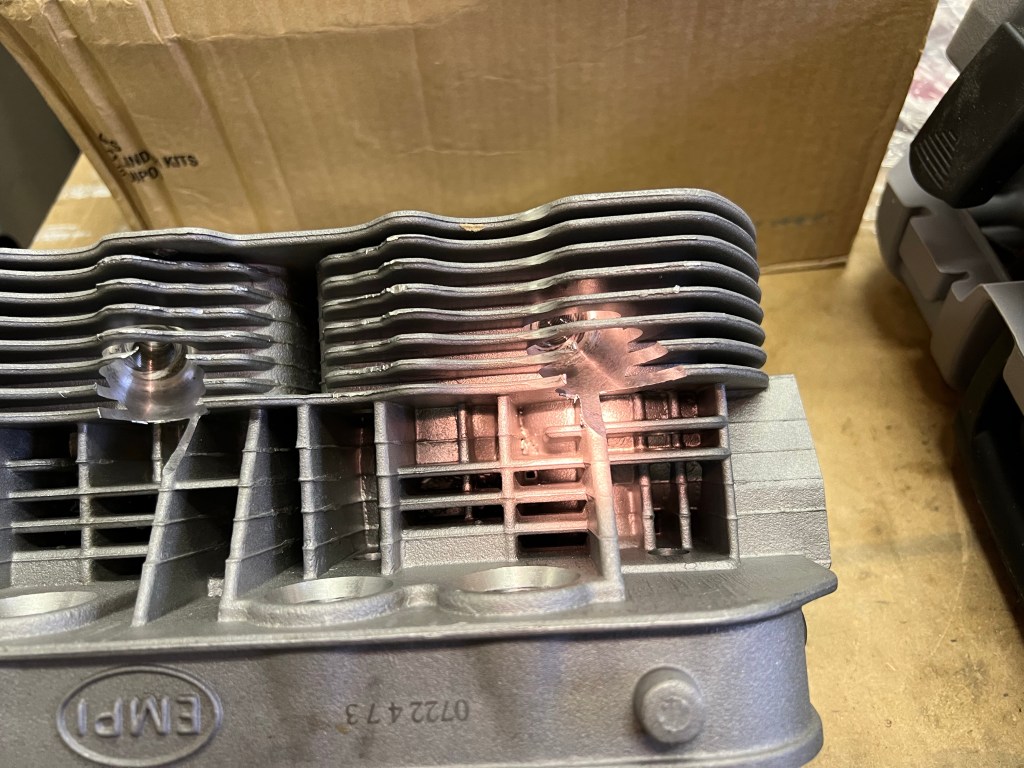

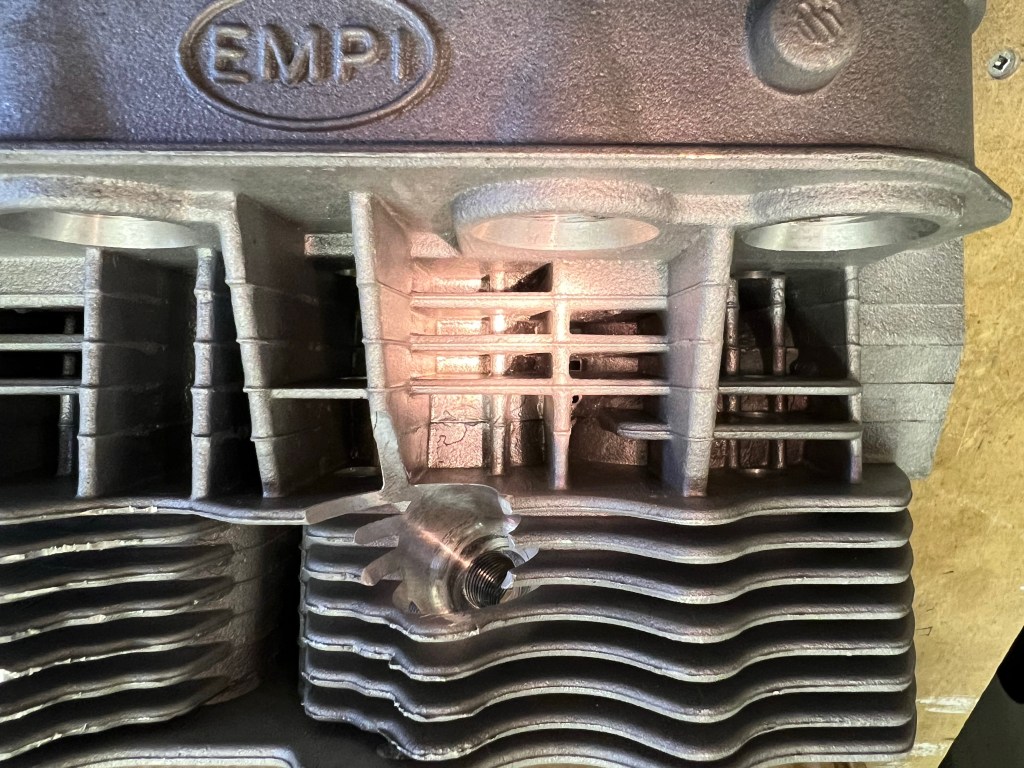

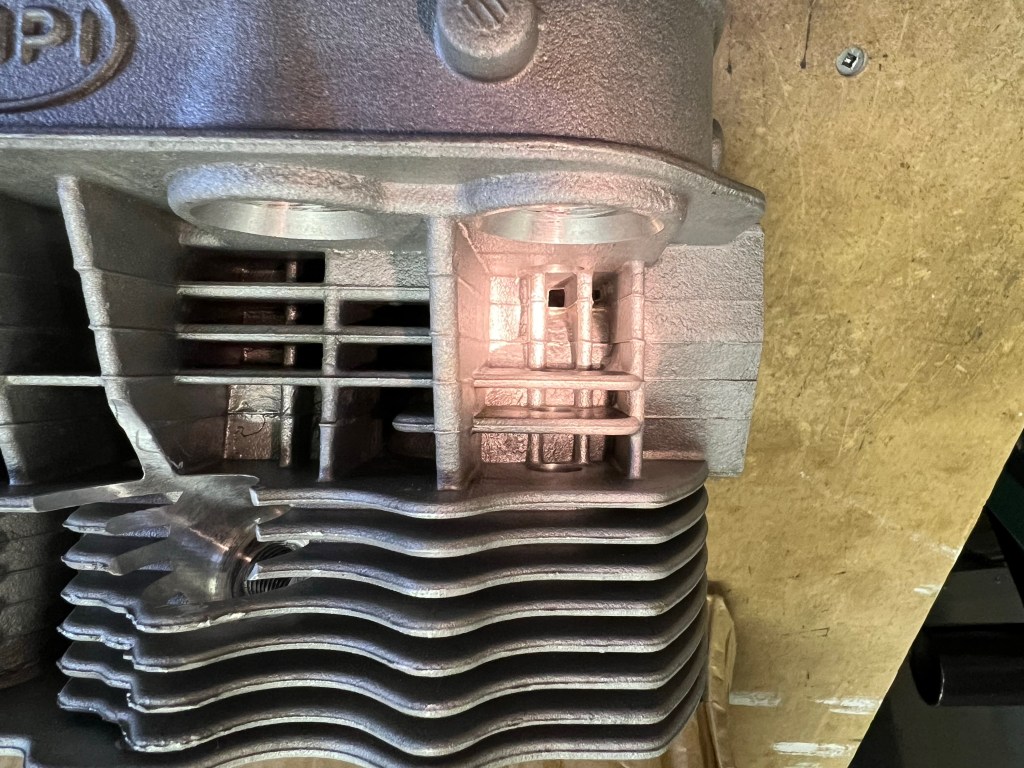

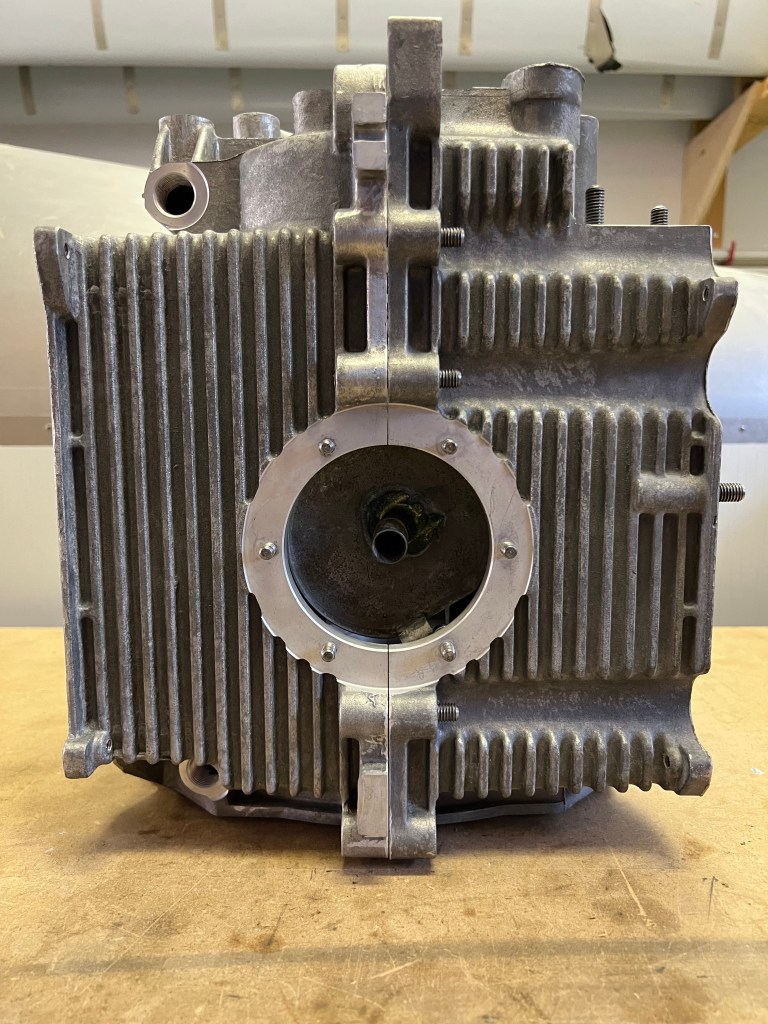

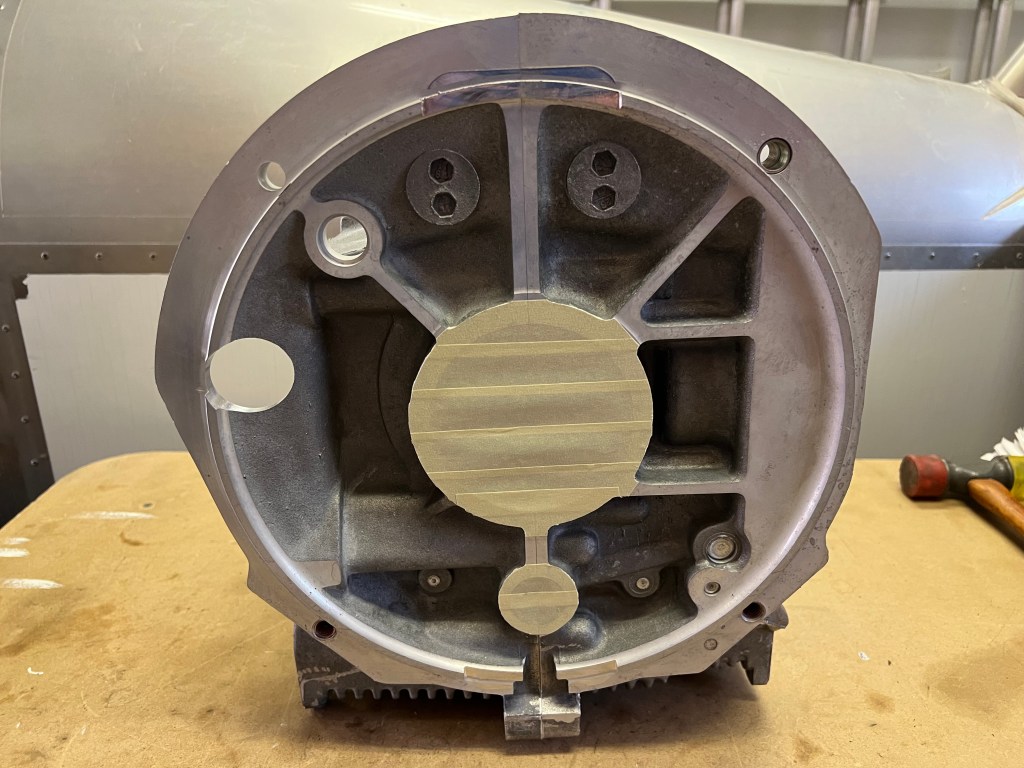

After installing the cylinders and spacers, I installed the cylinder head with the head gaskets and push rod tubes. Next, I measured and started trimming the cylinder studs. I needed to cut down 5 of these to ensure clearance from the rockers and the intake manifold. For each of these, I used some form a gasket on the threads to the crank case as I reinstalled the studs. I plan to do the same for the remaining studs after re-installing the studs that I cut down

You must be logged in to post a comment.