I started today by getting out the cylinders heads. I want to have them ready to install right after I install the cylinders. Why? The cylinders are installed using Permatex Aviation Form-A-Gasket #3 and I would like to install the cylinder heads and have them secured while the Permatex cures. Since I only work on the engine in frequently I did not want to install the cylinders and then leave them to sit for a few days or weeks until I got to the cylinder heads.

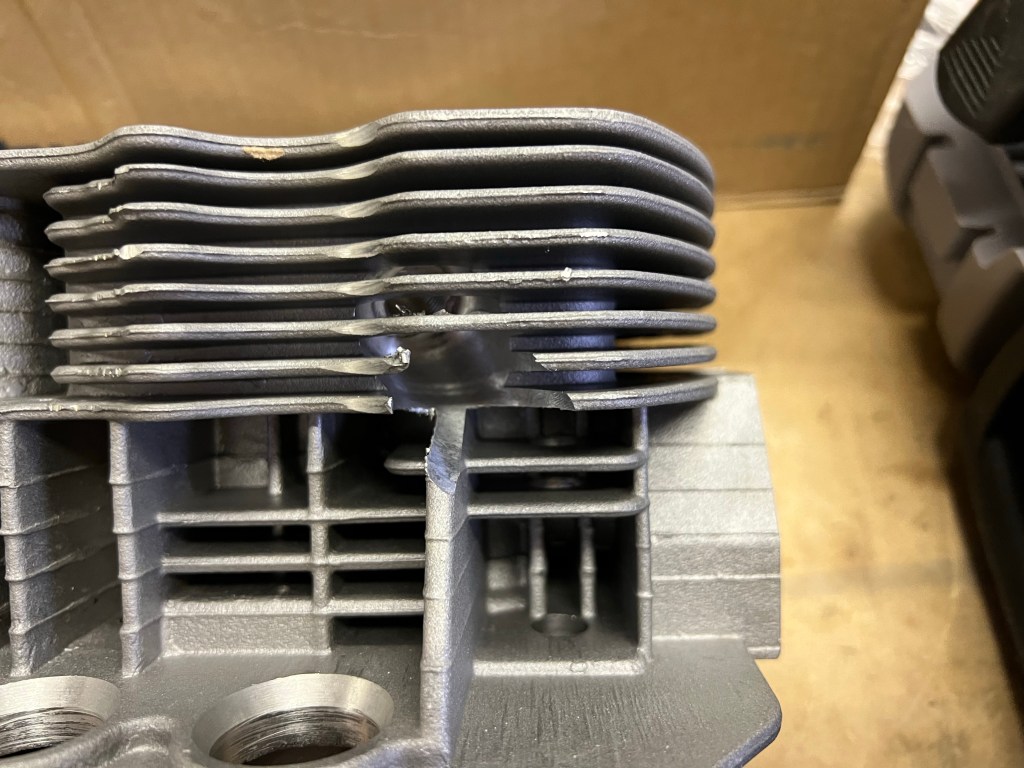

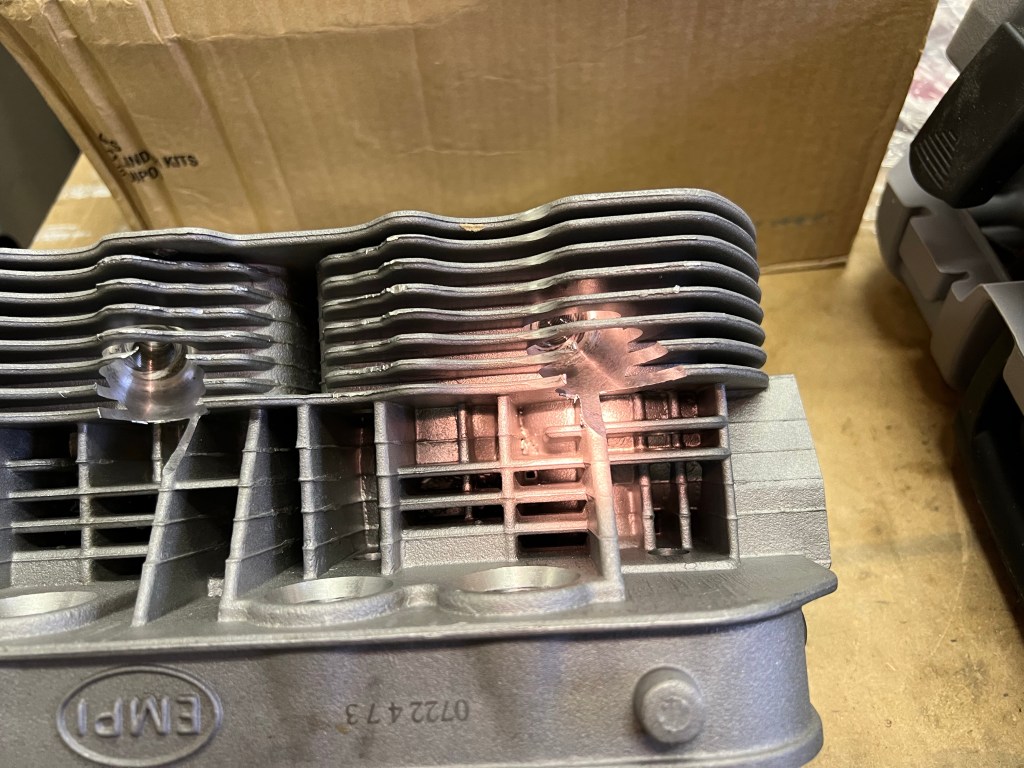

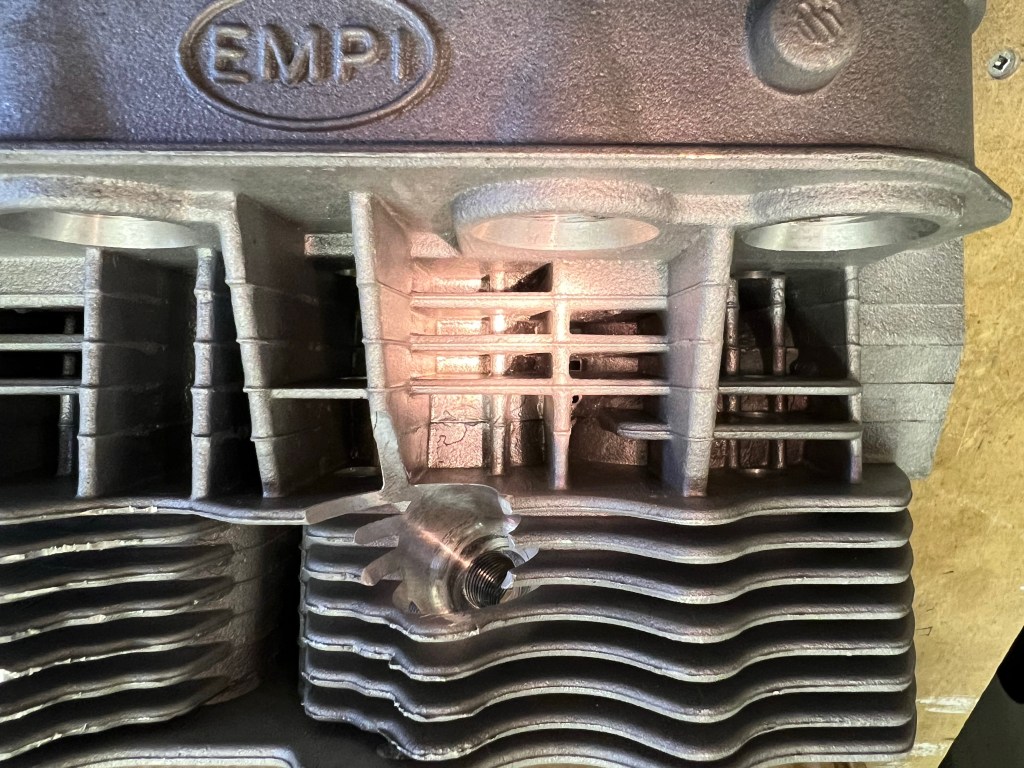

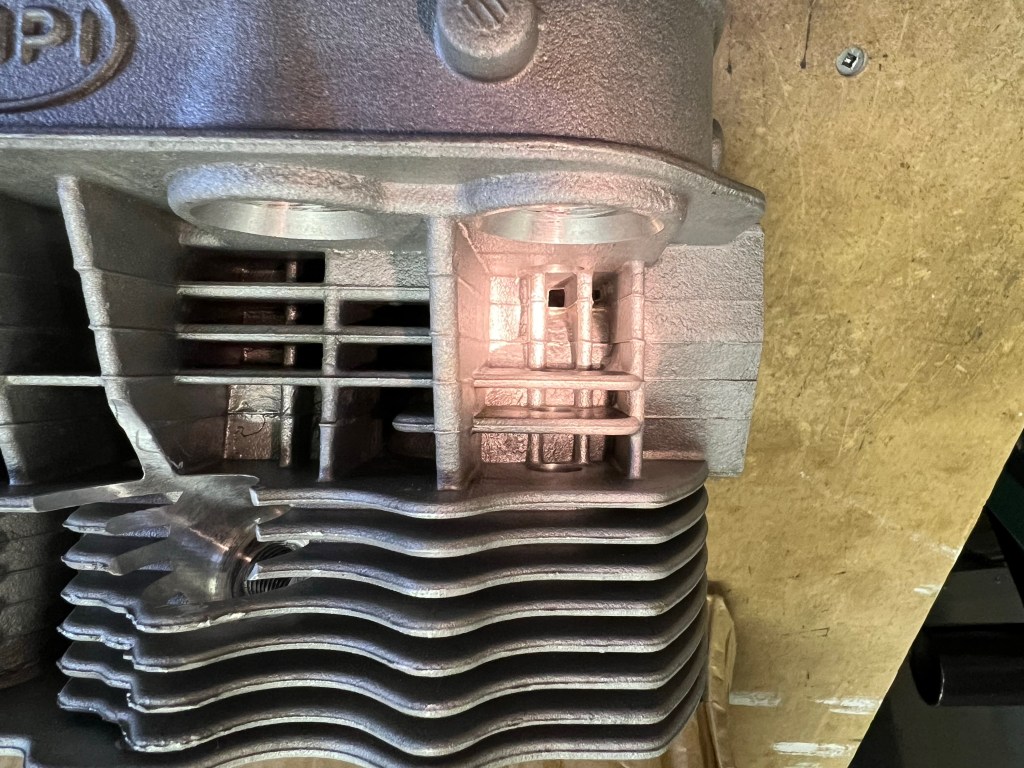

The instruction to clean the heads of machining debris is shown in bold text and identified as Important right after the parts required list. Hopefully, nobody skips ahead to the first step without doing the required cleaning. I found alot of debris in my heads.

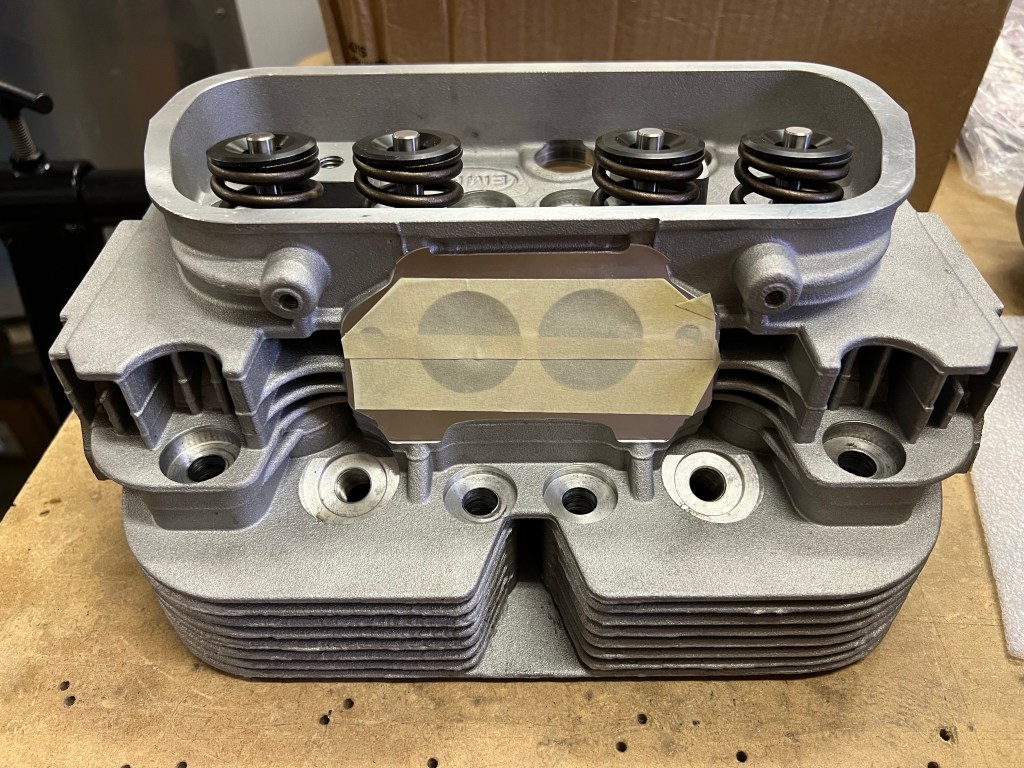

Before I started working on the chips I used masking tape to close up the intake and exhaust ports. I still planned to blow these out later but I figured it was better to keep the chips out of there right from the start.

I used a small scrapper and a deburring tool to remove the worst of the aluminum chips. I also used a piece of bare 14 gauge copper wire to get to the bottom of some of the tight areas to get the chips out. In the areas where the secondary spark plug holes were added, I cleaned up the sharp areas with a Dremel tool and then some scotch bright pads to break the sharp edges. I used compressed air on several occasions to blow out the chips.

You must be logged in to post a comment.