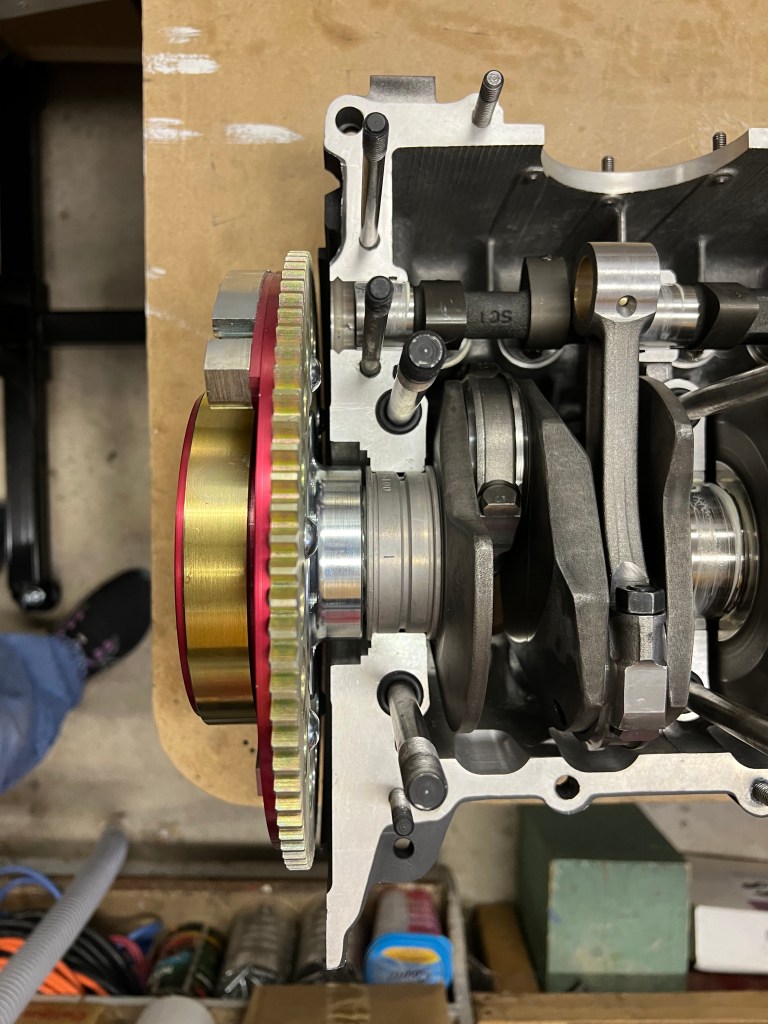

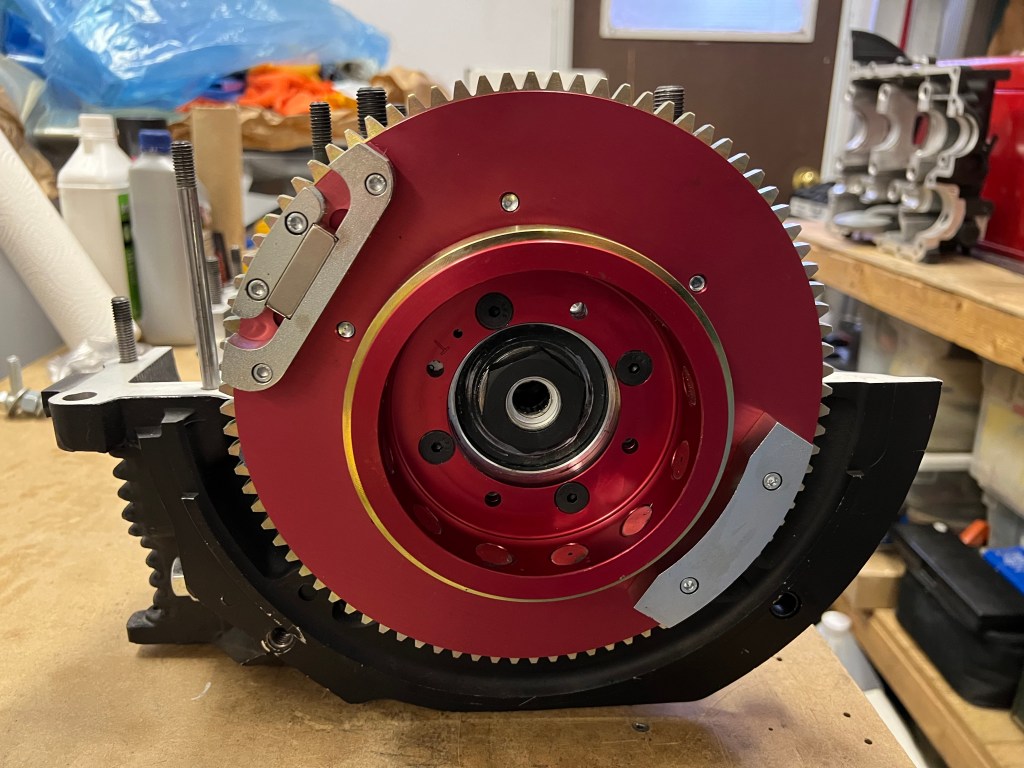

I continued working on assembling the crankcase today. Previously, I installed the crankshaft and camshaft. Today, I finished fitting the flywheel. This took a bit of polishing of the dowel pin holes as I could not get the flywheel to fit onto the end of the crankshaft.

Once the flywheel was installed, I used my impact gun to tighten the 36 mm bolt. Next, I measured the crankshaft end play and recorded the measurement in my installation manual. It measured 0.061″. This means that I need a shim thickness stack of 0.055″ to 0.058″ to provide the required 0.003″ to 0.006″ end play.

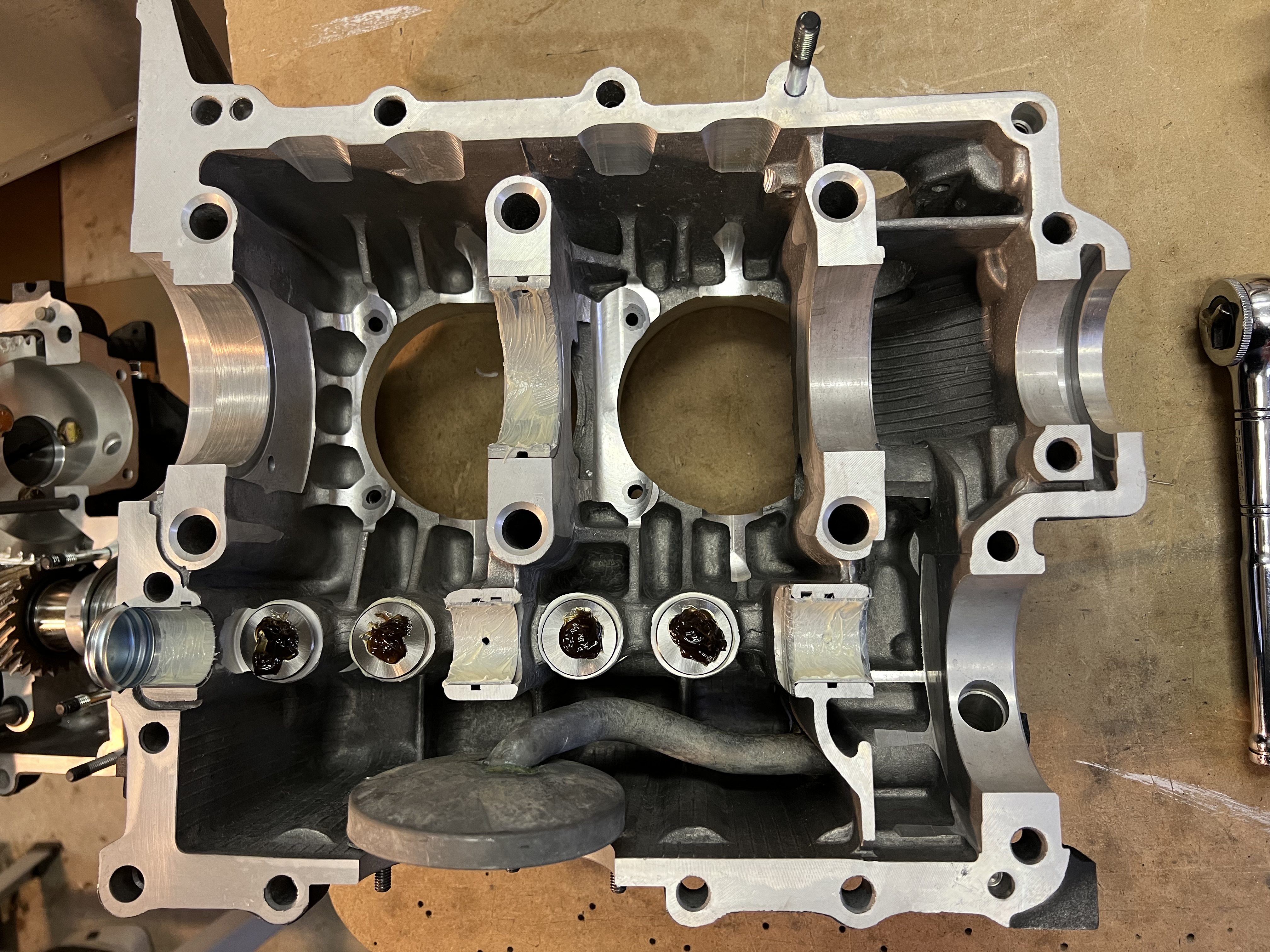

Once the end play was determined, I found the fasteners and cam plug I needed to assemble the two crankcase halves. I installed the lifters and applied the grease to them. I lubricated the bearing halves for the camshaft and crankshaft. Next, I applied the Permatex Aviation Form-A-Gasket #3 to the case half that does not have the studs.

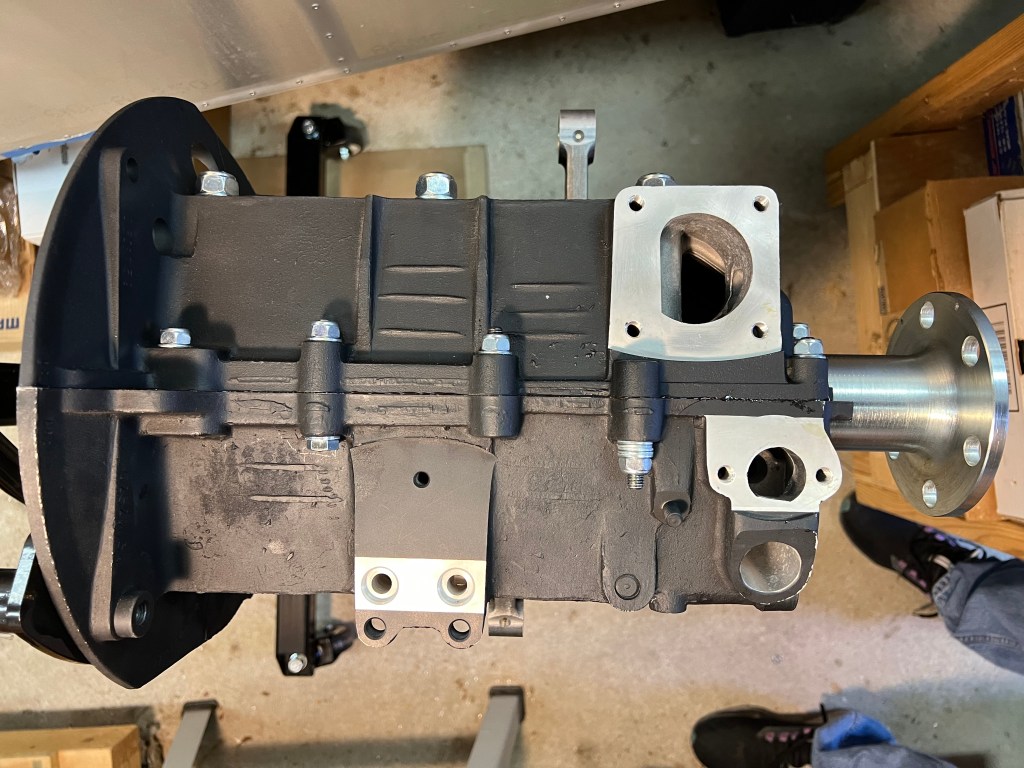

After applying the Permatex, I assembled the case halves and followed up with the torquing sequence for all the fasteners. The manual mentions 10 studs for the AVC-Z01-23 stop nut. I had a hard time finding all 10, but in the end, one faces the opposite way and needs a bunch of washers to allow the nut to tighten up on the stud.

You must be logged in to post a comment.